You are searching for an effective and modern latex foam production process for pillows, mattresses and

toppers with the latest state-of-the-art equipment? Old fashioned systems bothering your mind and you prefer

to use a new manufacturing process to develop new products for your customers with additional ergonomic

features and benefits ?

I offer you a wide range of consultancy and support in this special industry.

Let me tell you my story:

Welcome on LATEXFOAM TECHNOLOGY!

Natural latex is the “liquid milk” tapped from the rubber tree Hevea Brasiliensis. Its main cultivation areas in

Asia are responsible for more then 90% of the world natural rubber production of 12.314 thousand metric tons

(2015) of which liquid latex has only a small share of about 10%. After gathering the liquid latex in the

plantations it is concentrated and preserved with some ammonia and TMTD/ZnO. This standardized LA-latex

(low-ammonia latex) is the basis for dipping products such as condoms, balloons and gloves but also for latex

foam goods such as mattress cores and pillows.

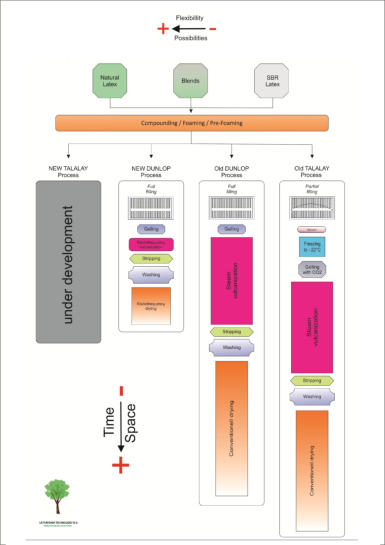

In 1887, John Boyd DUNLOP (1840 –1921), born in Scotland, developed the first practical pneumatic or

inflatable tire for his son's tricycle, tested it and patented it on December 7, 1888. Even two years later his

patent becomes officially invalid because the Scottish inventor Robert William Thomson (1822 - 1873) had

patented the same idea already in GB, France (1846) and in the US (1847), DUNLOP from now on was the

eponym for this vulcanization process.

1929 E. A. Murphy established the first standardized method for foaming latex at DUNLOPILLO in Great

Britain.

This “DUNLOP process” for vulcanizing latex foam for mattresses and pillows did not change significantly

since these early days. Some chemicals has been replaced cause of small developments but the

fundamental chemical process, the cross-linking of rubber molecules with sulphur, is still the same.

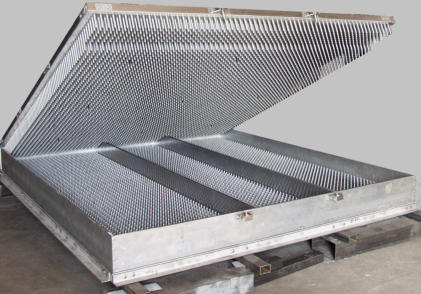

In short the latex compound is mixed up (foamed) with air, transferred into a metal mould (made of steel

and/or aluminium) with hundred of pins and heated (vulcanized) in a steam chamber or tunnel.

The distances between the pins and their numbers are defined by the fact of the slow heat transfer which is

an indirect one: The saturated steam in the vulcanizing chamber initially transfers the heat to the surface of

the mould and from there the energy is moving slowly inside the foam through the pins until the foam inside

is reaching the required vulcanizing temperature of about 100°C.

Looking deeper into the facts for a US Queen Size mattress with 60 in × 80 inch:

The dry volume of such a mattress (pins are not taken into consideration here) is about 460 litres. At an

average density of 130 grams per litre (wet foam) the weight of latex is ab. 60 kg only. The rest (400 litres) is

simply air which unfortunately is working as an insulator and poorly heatable. For such a mattress core a

vulcanization time up to one hour is not uncommon. The weight of such a metal mould could sum up to 1.200

kg! Thus more than one ton of metal is heated up to vulcanize just only 60 kg of wet latex foam and it is

obvious that such a production system needs a very heavy support structure. Also it is evidently that such a

system is inflexible and slow in regards in general handling like mould opening, closing and exchange. Now

you may want to know what‘s different in my process?

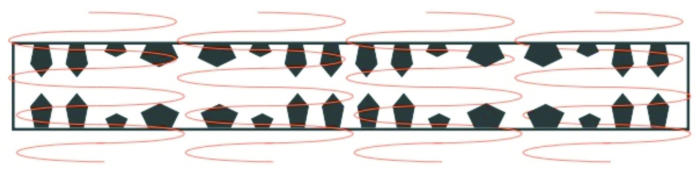

As against the conventional DUNLOP process, the method I invented is working on the basis of high

frequency heating technology, by which the water molecules inside the latex foam are heated by high

movement caused by their dipole character. Without the diversion through metal, the latex foam is reaching

vulcanization temperature within minutes! This means substantial energy and time saving.

The advantages of this new production

process can be summarized as follows:

•

High Energy Saving

•

Export Product Quality

•

Reduced Space Requirements

•

High Flexibility in Shapes and Sizes

•

New Designs and Product Features

•

Faster Reaction to Market Response

•

Faster ROI

•

Higher Profit

•

In-house Manufacturing of Moulds

This is not the place to enumerate all possibilities

- of which up to now not all have been realized

- but in a personal meeting I would be glad to

discuss further details with you.

Get in touch to discuss more:

WhatsApp: +4915231852629

You are searching for an effective and modern latex foam production

process for pillows, mattresses and toppers with the latest state-of-

the-art equipment? Old fashioned systems bothering your mind and

you prefer to use a new manufacturing process to develop new

products for your customers with additional ergonomic features and

benefits ?

I offer you a wide range of consultancy and support in this special

industry.

Let me tell you my story:

Welcome on LATEXFOAM TECHNOLOGY!

Natural latex is the “liquid milk” tapped from the rubber tree Hevea

Brasiliensis. Its main cultivation areas in Asia are responsible for

more then 90% of the world natural rubber production of 12.314

thousand metric tons (2015) of which liquid latex has only a small

share of about 10%. After gathering the liquid latex in the plantations

it is concentrated and preserved with some ammonia and

TMTD/ZnO. This standardized LA-latex (low-ammonia latex) is the

basis for dipping products such as condoms, balloons and gloves

but also for latex foam goods such as mattress cores and pillows.

In 1887, John Boyd DUNLOP (1840 –1921), born in Scotland,

developed the first practical pneumatic or inflatable tire for his

son's tricycle, tested it and patented it on December 7, 1888.

Even two years later his patent becomes officially invalid because

the Scottish inventor Robert William Thomson (1822 - 1873) had

patented the same idea already in GB, France (1846) and in the

US (1847), DUNLOP from now on was the eponym for this

vulcanization process.

1929 E. A. Murphy established the first standardized method for

foaming latex at DUNLOPILLO in Great Britain.

This “DUNLOP process” for vulcanizing latex foam for mattresses

and pillows did not change significantly since these early days.

Some chemicals has been replaced cause of small developments

but the fundamental chemical process, the cross-linking of rubber

molecules with sulphur, is still the same.

In short the latex compound is mixed up (foamed) with air,

transferred into a metal mould (made of steel and/or aluminium)

with hundred of pins and heated (vulcanized) in a steam chamber

or tunnel.

The distances between the pins and their numbers are defined by

the fact of the slow heat transfer which is an indirect one: The

saturated steam in the vulcanizing chamber initially transfers the

heat to the surface of the mould and from there the energy is

moving slowly inside the foam through the pins until the foam

inside is reaching the required vulcanizing temperature of about

100°C.

Looking deeper into the facts for a US Queen Size mattress with

60 in × 80 inch:

The dry volume of such a mattress (pins are not taken into

consideration here) is about 460 litres. At an average density of 130

grams per litre (wet foam) the weight of latex is ab. 60 kg only. The

rest (400 litres) is simply air which unfortunately is working as an

insulator and poorly heatable. For such a mattress core a

vulcanization time up to one hour is not uncommon. The weight of

such a metal mould could sum up to 1.200 kg! Thus more than one

ton of metal is heated up to vulcanize just only 60 kg of wet latex

foam and it is obvious that such a production system needs a very

heavy support structure. Also it is evidently that such a system is

inflexible and slow in regards in general handling like mould

opening, closing and exchange. Now you may want to know what‘s

different in my process?

As against the conventional DUNLOP process, the method I

invented is working on the basis of high frequency heating

technology, by which the water molecules inside the latex foam are

heated by high movement caused by their dipole character. Without

the diversion through metal, the latex foam is reaching vulcanization

temperature within minutes! This means substantial energy and time

saving.

The advantages of this new production

process can be summarized as follows:

•

High Energy Saving

•

Export Product Quality

•

Reduced Space Requirements

•

High Flexibility in Shapes and Sizes

•

New Designs and Product Features

•

Faster Reaction to Market Response

•

Faster ROI

•

Higher Profit

•

In-house Manufacturing of Moulds

This is not the place to enumerate all possibilities

- of which up to now not all have been realized

- but in a personal meeting I would be glad to

discuss further details with you.

Get in touch to discuss more:

WhatsApp: +4915231852629

You are searching for an effective and modern latex foam production process for pillows, mattresses and toppers with the latest state-of-the-art

equipment? Old fashioned systems bothering your mind and you prefer to use a new manufacturing process to develop new products for your

customers with additional ergonomic features and benefits ?

I offer you a wide range of consultancy and support in this special industry.

Let me tell you my story:

Welcome on LATEXFOAM TECHNOLOGY!

Natural latex is the “liquid milk” tapped from the rubber tree Hevea Brasiliensis. Its main cultivation areas in Asia are responsible for more then 90%

of the world natural rubber production of 12.314 thousand metric tons (2015) of which liquid latex has only a small share of about 10%. After

gathering the liquid latex in the plantations it is concentrated and preserved with some ammonia and TMTD/ZnO. This standardized LA-latex (low-

ammonia latex) is the basis for dipping products such as condoms, balloons and gloves but also for latex foam goods such as mattress cores and

pillows.

In 1887, John Boyd DUNLOP (1840 –1921), born in Scotland, developed the first practical pneumatic or inflatable tire for his son's tricycle, tested it

and patented it on December 7, 1888. Even two years later his patent becomes officially invalid because the Scottish inventor Robert William

Thomson (1822 - 1873) had patented the same idea already in GB, France (1846) and in the US (1847), DUNLOP from now on was the eponym for

this vulcanization process.

1929 E. A. Murphy established the first standardized method for foaming latex at DUNLOPILLO in Great Britain.

This “DUNLOP process” for vulcanizing latex foam for mattresses and pillows did not change significantly since these early days. Some chemicals

has been replaced cause of small developments but the fundamental chemical process, the cross-linking of rubber molecules with sulphur, is still the

same.

In short the latex compound is mixed up (foamed) with air, transferred into a metal mould (made of steel and/or aluminium) with hundred of pins

and heated (vulcanized) in a steam chamber or tunnel.

The distances between the pins and their numbers are defined by the fact of the slow heat transfer which is an indirect one: The saturated steam

in the vulcanizing chamber initially transfers the heat to the surface of the mould and from there the energy is moving slowly inside the foam

through the pins until the foam inside is reaching the required vulcanizing temperature of about 100°C.

Looking deeper into the facts for a US Queen Size mattress with 60 in × 80 inch:

The dry volume of such a mattress (pins are not taken into consideration here) is about 460 litres. At an average density of 130 grams per litre

(wet foam) the weight of latex is ab. 60 kg only. The rest (400 litres) is simply air which unfortunately is working as an insulator and poorly

heatable. For such a mattress core a vulcanization time up to one hour is not uncommon. The weight of such a metal mould could sum up to

1.200 kg! Thus more than one ton of metal is heated up to vulcanize just only 60 kg of wet latex foam and it is obvious that such a production

system needs a very heavy support structure. Also it is evidently that such a system is inflexible and slow in regards in general handling like

mould opening, closing and exchange. Now you may want to know what‘s different in my process?

As against the conventional DUNLOP process, the method I invented is working on the basis of high frequency heating technology, by which

the water molecules inside the latex foam are heated by high movement caused by their dipole character. Without the diversion through metal,

the latex foam is reaching vulcanization temperature within minutes! This means substantial energy and time saving.

The advantages of this new production

process can be summarized as follows:

•

High Energy Saving

•

Export Product Quality

•

Reduced Space Requirements

•

High Flexibility in Shapes and Sizes

•

New Designs and Product Features

•

Faster Reaction to Market Response

•

Faster ROI

•

Higher Profit

•

In-house Manufacturing of Moulds

This is not the place to enumerate all possibilities

- of which up to now not all have been realized

- but in a personal meeting I would be glad to

discuss further details with you.

Get in touch to discuss more:

WhatsApp: +4915231852629